Introduction

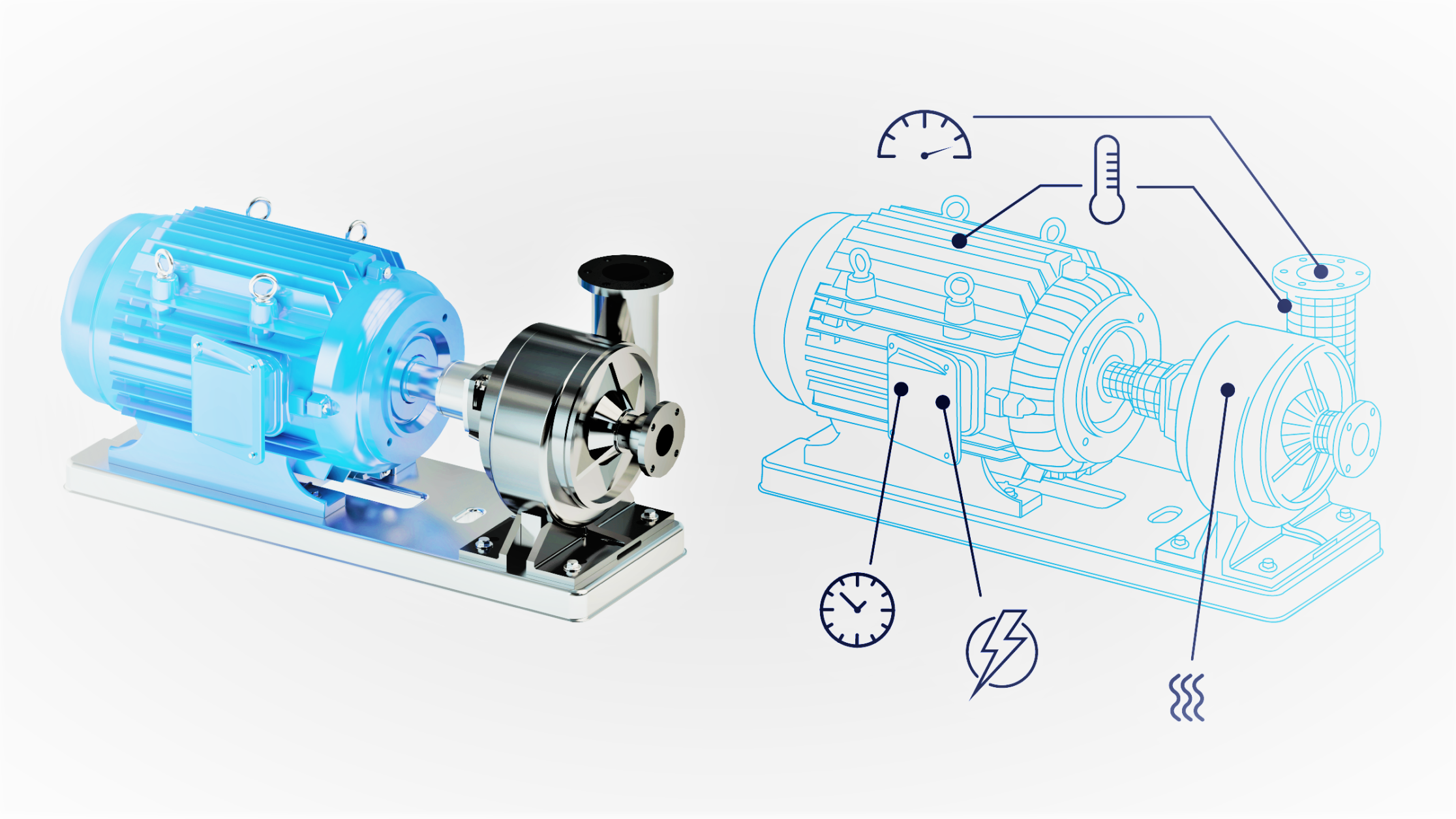

In the last two years, we heard a lot about the Digital Twin and its application within the manufacturing industry and prototyping, nowadays, the concept of the Digital Twin had been introduced to the construction industry in different ways, for the successful achievement of the Digital Twin Approach, more adaption, and series steps need to be taken into consideration, this article will introduce a very fast and smart way on how can you implement the Digital Twin with a minor cost.

The Digital Twin Concept & Definition:

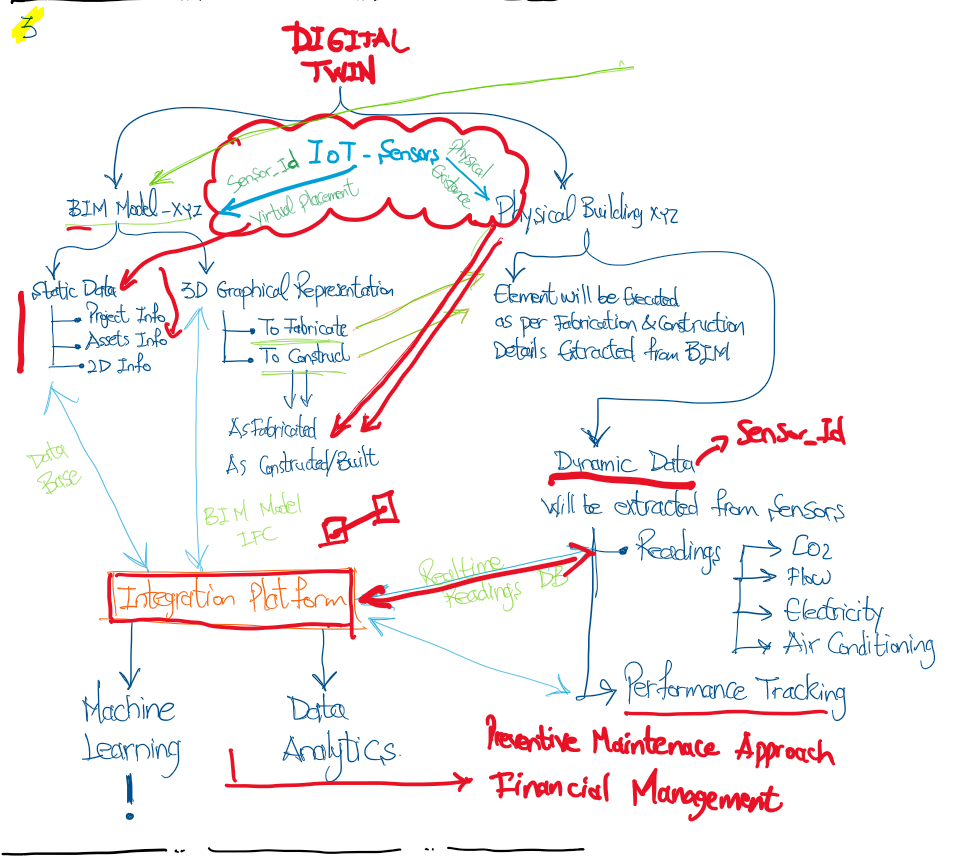

Digital Twin is simply a replica of the physical facility in a digital environment and vice versa. The concept of the Digital Twin dates back to a University of Michigan presentation to the industry in 2002 for the formation of a Product Lifecycle Management (PLM) center. Hence it was mainly articulated for the manufacturing and products industry.

The Framework of Digital Twin in AECO Industry:

Nowadays, AECO industry try to cope with the digitalization revolution that we are witnessing, they are trying to reflect the Digital Twin concept on the construction industry starting from the early phase of the project.

Digital Twin is a strategic framework that shall be defined in any project brief and pre-conceptual stage, in which, Owners and Developers will have a clear roadmap as they are moving forward.

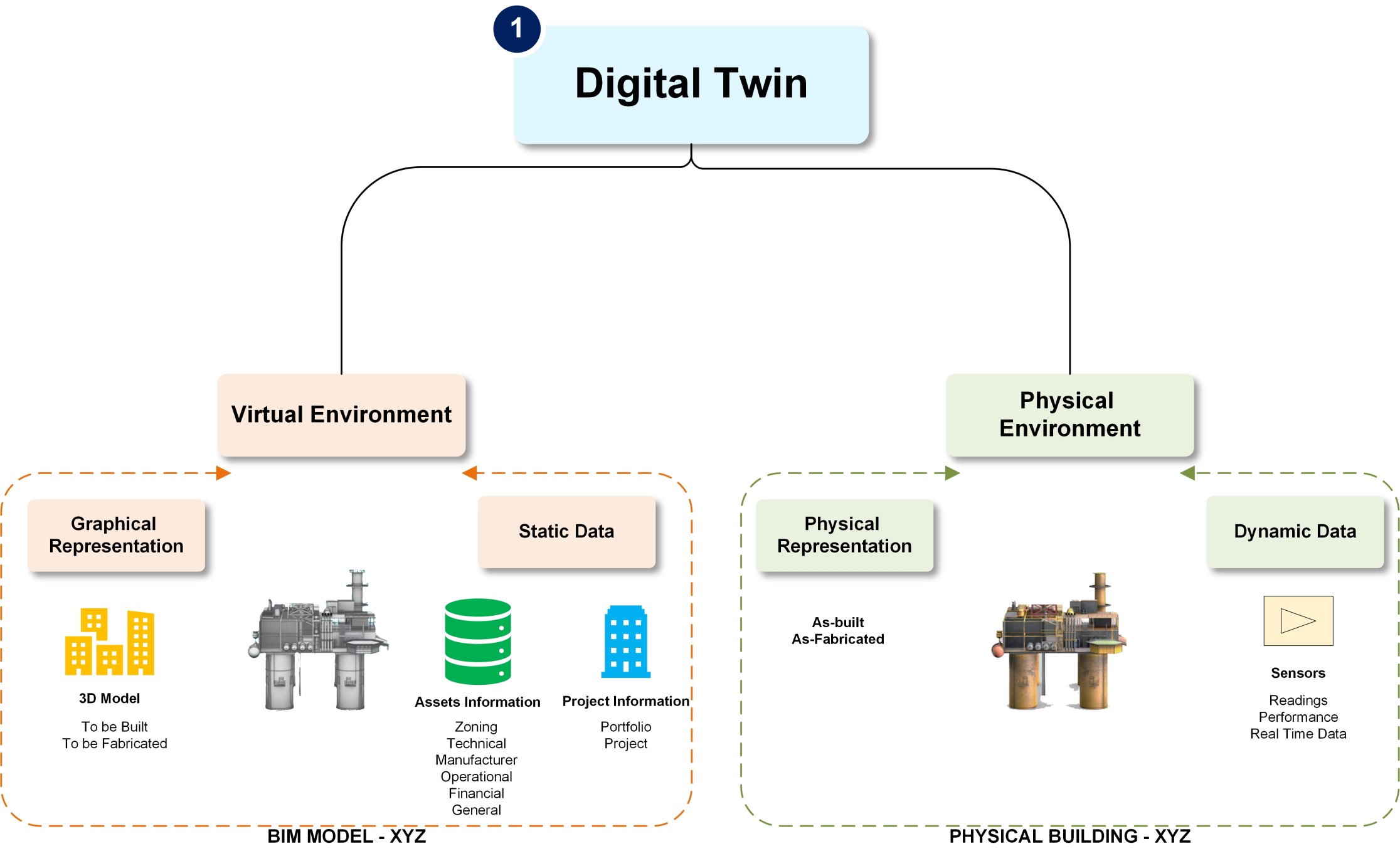

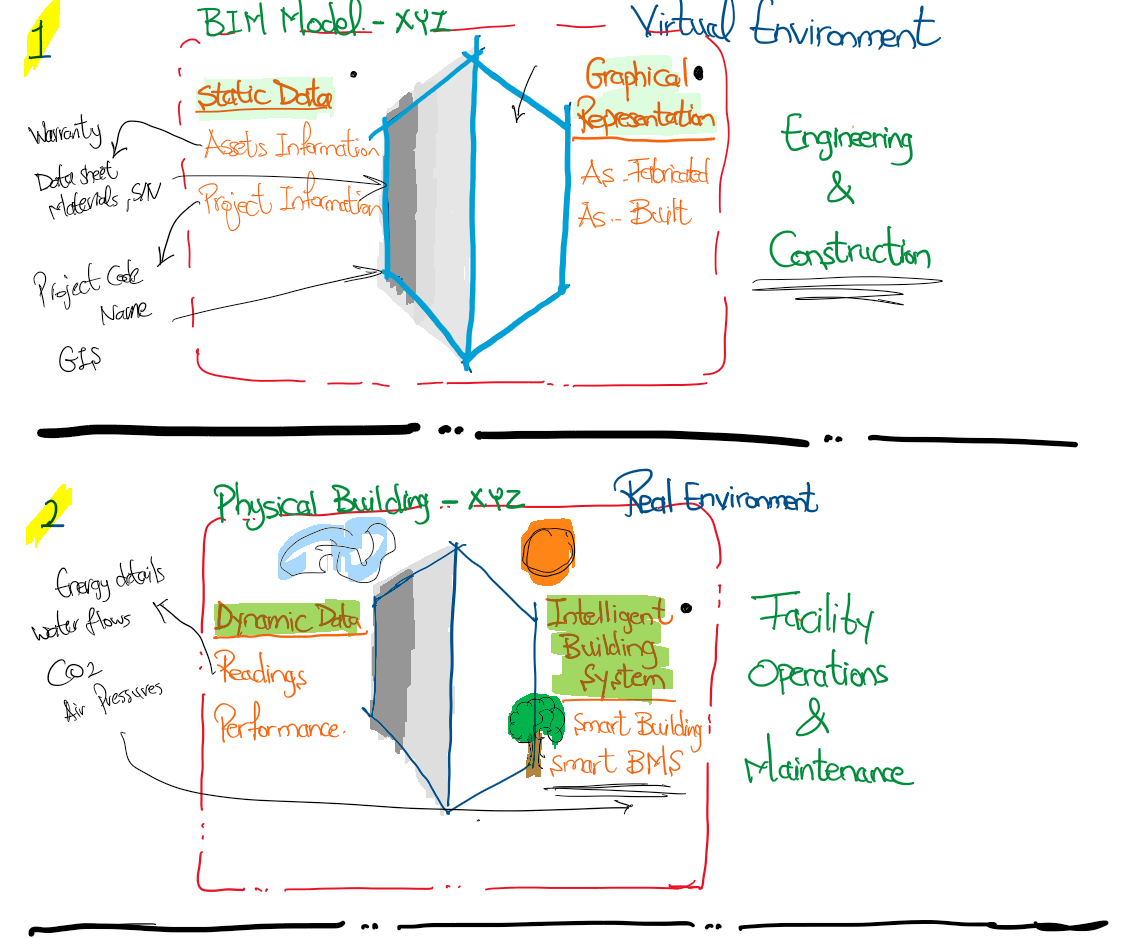

The Digital Twin to be achieved mainly depends on two main pillars as following:

Static Data: The type of data that couldn’t be changed, updated, or removed, it’s the data that is filled and embedded within the BIM models during the design and construction phase, that is like:

Portfolio Information: Portfolio Name, Geo Location, GIS, Involvement

Project & Zoning Information

Assets Information: Warranty certificates, Datasheets, Assets information (manufacturer, serial no, catalogs, etc.), Assets location in the facility, Technical classification, and so on.

Dynamic Data: to achieve this type of data gathering you need to depend on IoT, in which you will install sensors and sensitive transmitters in the most of the maintainable assets in order to collect and gather readings and performance analysis on a daily, weekly, and/or monthly basis. These data will be synchronized with the Digital Model in a platform called Computer Aided Facility Management that will handle all the operations, additionally, it will be the host and receiver for both Static & Dynamic Data along with the Digital Model.

By having two-way (In & Out) data synchronization, you will achieve the digital twin.

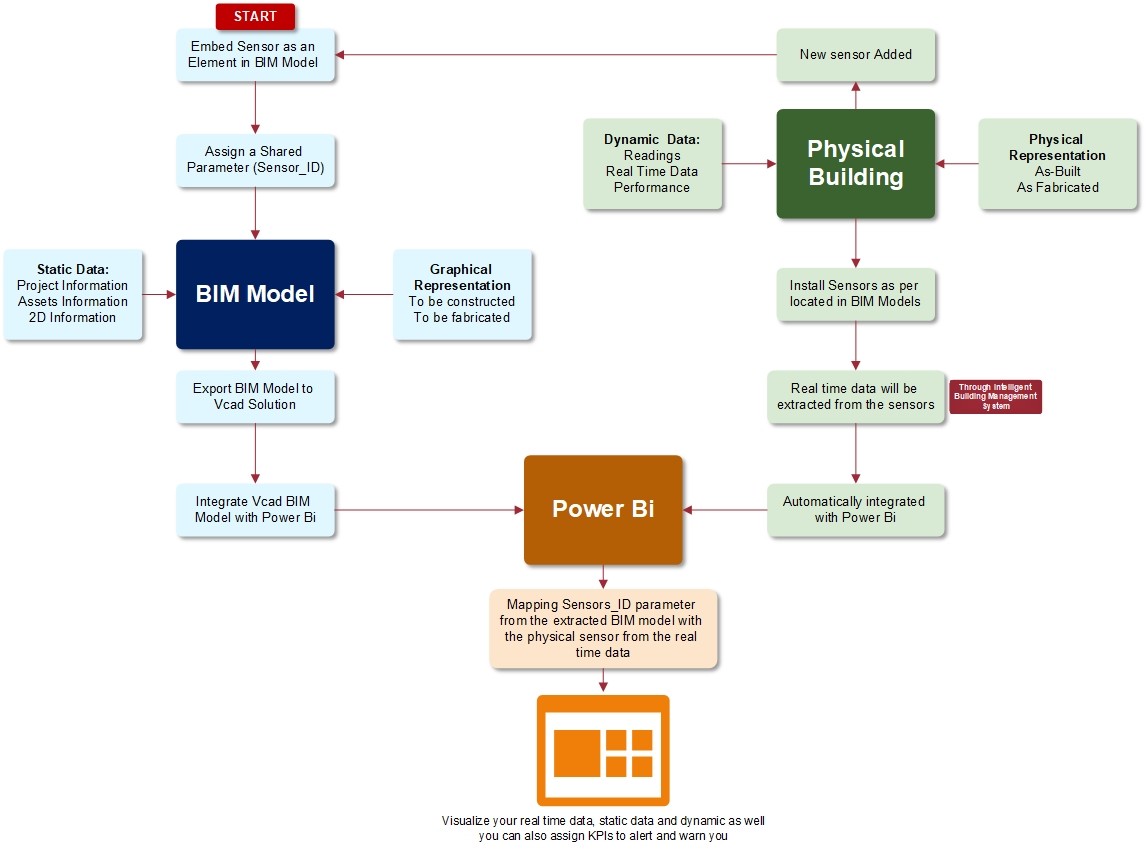

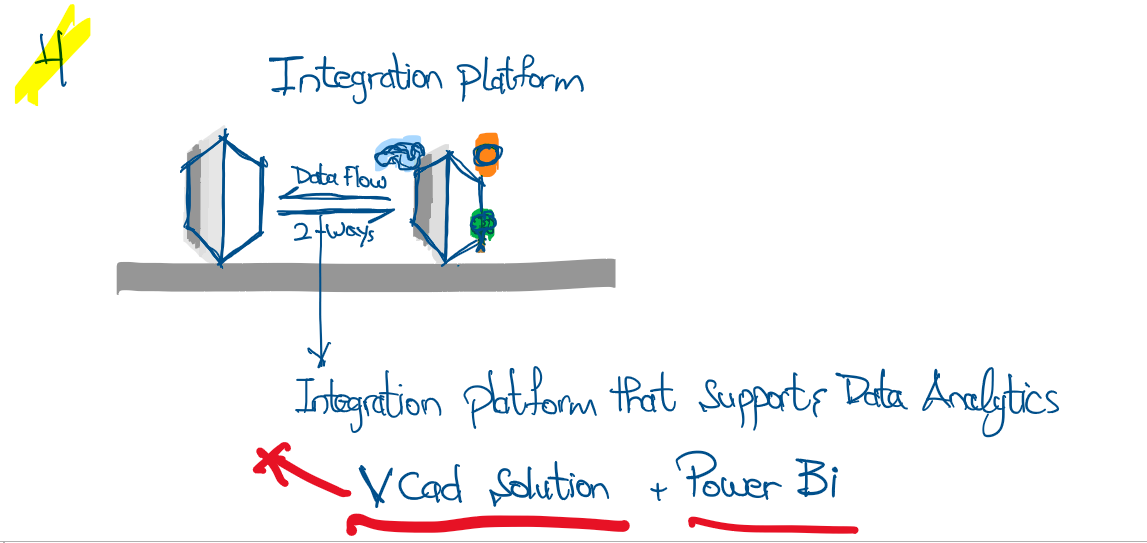

Integration Platform: VCAD solution + Power Bi

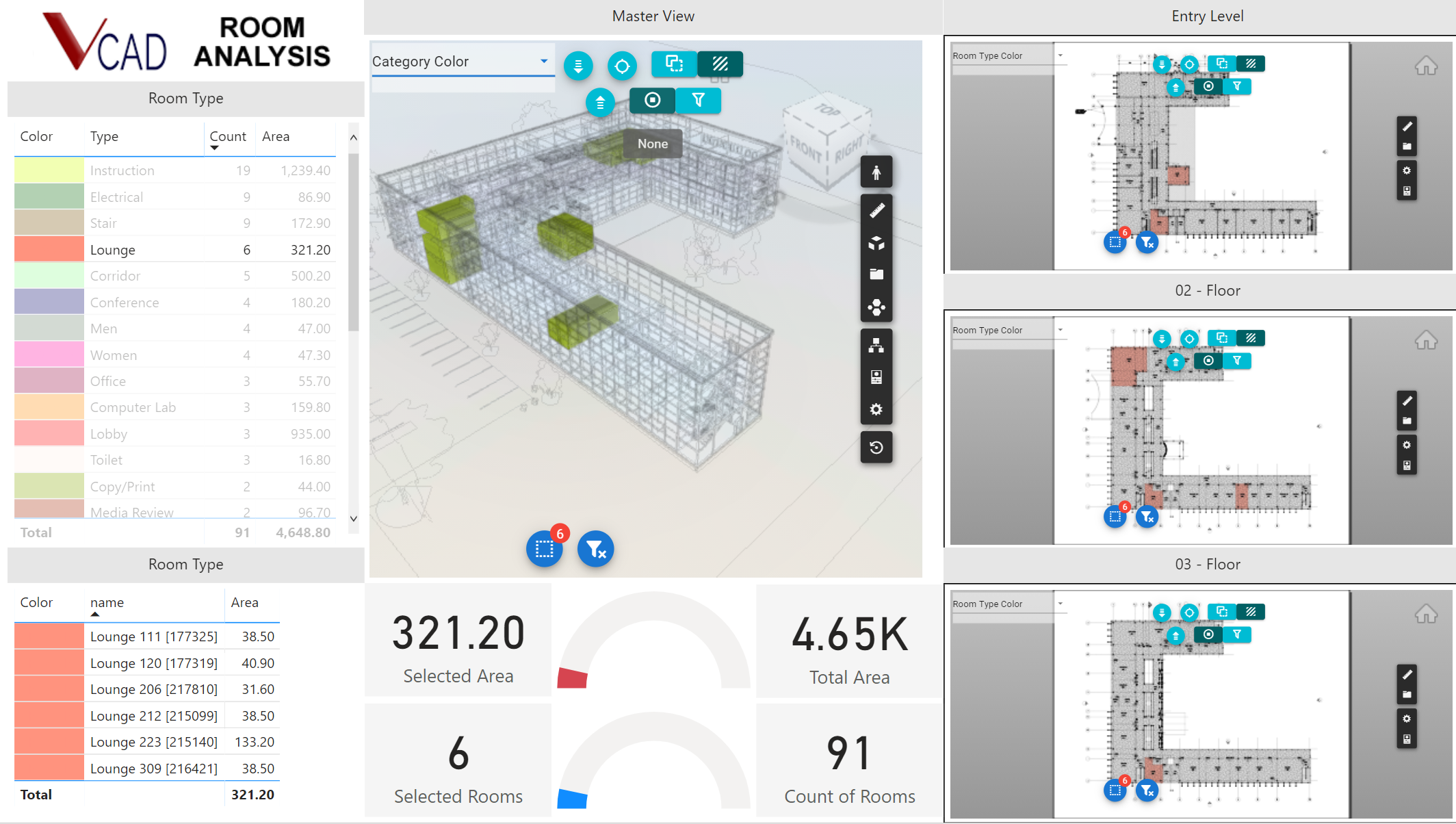

The form of data will be represented like the screenshot in the below figure, in which the model itself and both types of data are represented in one platform using VCAD Solution and its integration with the powerful data visualization software “Power Bi”.

The figure attached is a screenshot from the VCAD website itself and definitely, you can go to this link and try different reports and templates, hence you can utilize this solution within your Digital Twin Approach. Click Here

The Automation of Digital Twin

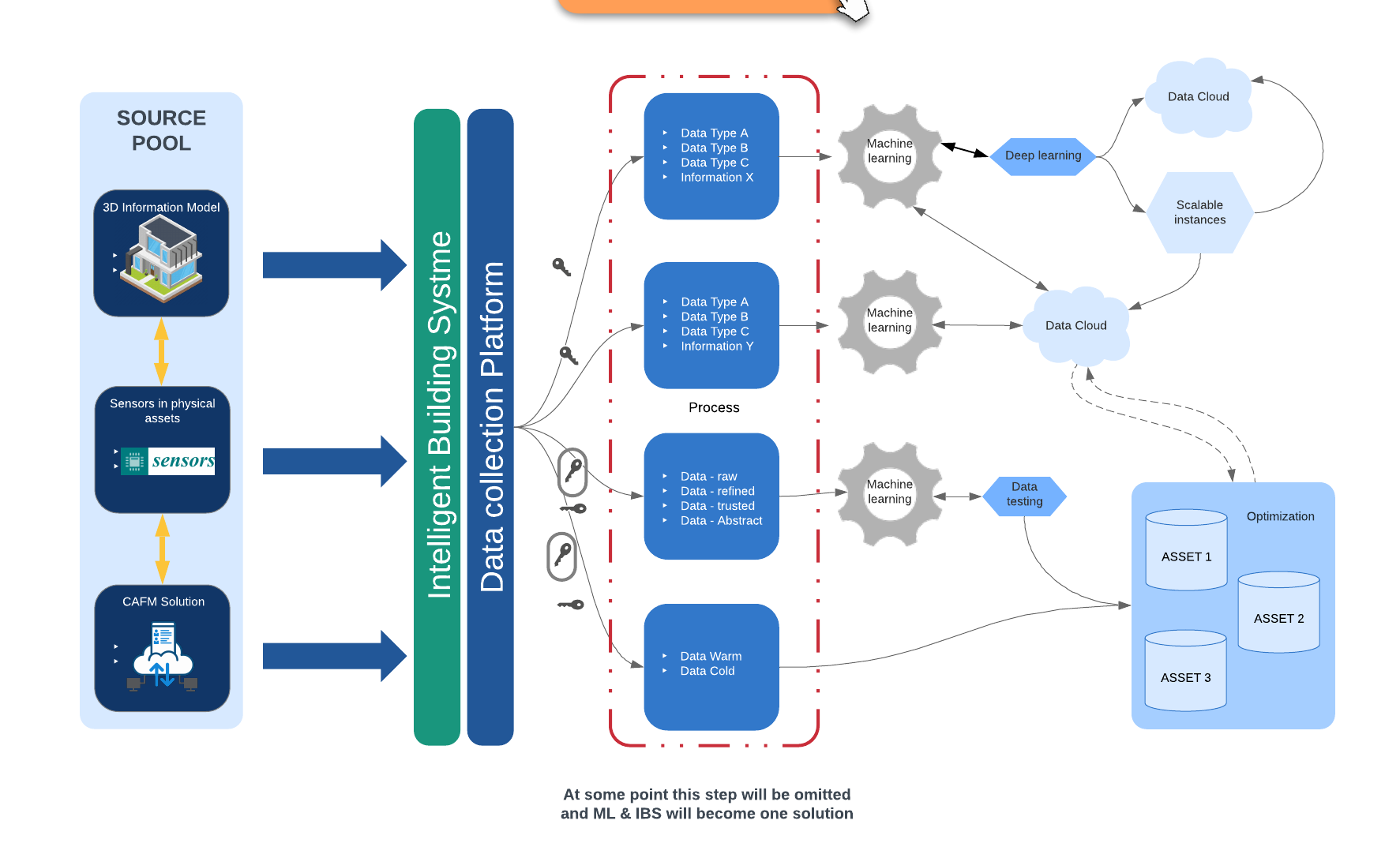

To have an efficient way of Digital Twin Management, AI shall be employed with a Machine Learning Engine, in which it will gather, collect and analyze data leveraging deep learning methodology to have the facility being managed remotely and digitally.

The methodology itself has no specific duration depending on the size of the facility as well as the quantity of needed data in order to run the ML Algorithms.

Initiate & Integrate Concept

These are the concepts that shall be followed while putting an in-house strategy for your assets to be managed in a Digital Twin Environment.

Initiate Concept: from the work initiation we can understand that this concept shall be utilized in the early phase of project definition and kick-off, hence it’s preferable for the NEW PROJECTS.

Integrate Concept: this will work with the existing assets and projects, in which 3D & Laser scanning will be leveraged in order to have a point cloud model that can be easily converted to a 3D BIM model, thanks to the current technology.

The Digital Twin Prerequisites and Benefits

In order to have a Digital Twin in place, the following shall be defined:

- Organization Information Requirements

- Assets Information Requirements along with Projects Information Requirements

- Intelligent Building System

- IoT Strategy (Solution Provider)

- CAFM Solution or Equivalent (Integration Platform & APIs)

- Reasonable Budget

Once we have the previous in house, we can be benefited from the Digital Twin approach for the following:

- Data-Driven Decision Making

- Preventive Maintenance

- Digital, Automated & Remote Assets Management

- Improved Efficiency

DID IT WAS INFORMATIVE?!

SHARE IT

FOR THE KNOWLEDGE TRANSFER AND FURTHER DEVELOPMENT AREAS

Ask for more from HERE

Sketches

The Digital Twin Capsule

Resources

https://venturebeat.com/2021/06/05/microsoft-paves-digital-twins-on-ramp-for-construction-real-estate/

https://venturebeat.com/2020/12/08/microsoft-launches-azure-digital-twins-in-general-availability/

Developments in digital twins

https://www.bimservices.it